Winmo (Shanghai) Automation Technology Co.,Ltd. website!

021-51097178 13501931621 15221778690

021-51097178 13501931621 15221778690

【Bright spot】

1、 WINMO High order double PLC hybrid network control;

2、DPH wafer design, to win more installation space.

【The keyword】 PLC HMI The inverter Temperature control module Peristaltic pump filling machine

【Preface】

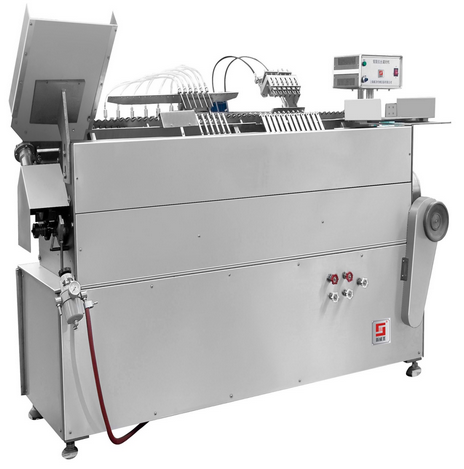

AAG series peristaltic pump filling machine is a new generation of single - machine multi - needle wire drawing filling and sealing machine. In the design, the rectangular bottle conveying mode makes the ampoule more stable and the bottle breaking rate lower. There is a new clutch device in the hopper bottle, which can stop the delivery of ampoules when the machine stops, so as to reduce the loss of ampoules. The electromagnetic switch is replaced by mechanical irrigation stop system with strong reliability. The bottling mechanism abandons the traditional bottling way, the bottling arrangement is more reasonable and the finished product is more efficient. Our factory is a domestic manufacturer of pharmaceutical machine using molded parts. The main parts are made of precision stainless steel castings to ensure the accuracy and interchangeability of the parts. Secondly, the use of stainless steel piston filling, control dripping phenomenon, prevent carbonization, stainless steel piston can also ensure the accuracy of loading.

【Text】

The electronic control system of peristaltic pump filling is mainly composed of three parts: bottle-free stop filling, power transmission and report data

【System structure】

1、HMI:PSM07PA

2、PLC:Host DPH*2 module DPH-4DA

3、Frequency converter: VFT series vector frequency converter

【System specifications】

The system is composed of two WinMO high-order wafer type DPH series PLC as the core, through high-speed pulse, accurately control the filling volume and filling speed of six stepper motors under the control.

At the same time, 4DA analog expansion module is used to realize the speed control of the spindle drive motor. Compared with the previous potentiometer knob scheme, the speed control mode is more flexible, and more suitable for centralized control of future networking, which is convenient for remote data acquisition and maintenance.

The essence of the scheme lies in the dual PLC design, which not only ensures the simultaneous control of multi-axis, but also combines with the DPH wafer shape. It has great adaptability to the complete set of electric cabinet space, and well realizes the combination of multi-position system.

As the machine's unique "no bottle stop filling" function, through the built-in convenient instructions of PLC, rapid shift, vacancy determination and detection, greatly reducing the difficulty of programming. At the same time, the added offset function can better meet the flexibility of debugging and installation of mechanical engineers on site, and ensure the rapid acceptance and delivery of equipment.

[scan]

[scan]