021-51097178 13501931621 15221778690

021-51097178 13501931621 15221778690

Principle of servo type selection

1. Continuous working torque < motor rated torque

2. Instantaneous MAX torque < MIN torque of servo motor (when accelerating)

3. Load inertia < 3 times motor rotor inertia

4. Continuous working speed < rated speed of motor

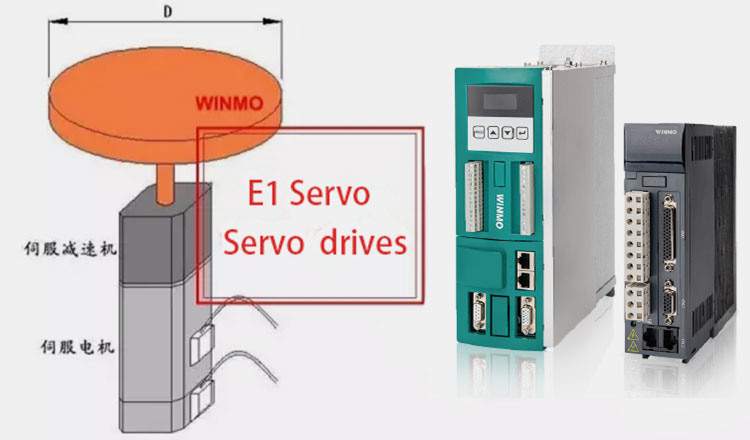

Calculate 1 for example

Known: disc mass M=50kg, disc diameter D=500mm, disc MAX speed 60rpm, please select servo motor and reducer.

Calculate the moment of inertia of the disk

JL=MD²/8=50*2500/8= 15625Kg. CM ² Assuming that the reduction ratio of the reducer is 1: R, then the inertia of load on the servo motor shaft is converted to 15625/R².

In accordance with the load inertia < 3 times the motor rotor inertia JM principle

If you choose 400W motor, JM=0.277kg. Cm ², then 15625/R² < 3*0.277,R² > 18803,R BBB>7 output speed =3000/137=22rpm, can not meet the requirements.

If 500W motor is selected, JM=8.17kg.cm², then 15625/R² < 3*8.17,R² > 637,R BBB> output speed =2000/25=80rpm, meet the requirements.

This transmission mode of resistance is very small, ignoring the torque calculation.

This transmission mode is the same as the previous transmission mode, and the calculation of load inertia is mainly considered in the selection, and the calculation formula is the same as the previous one.

Conclusion: the rotary load mainly considers the calculation of inertia.

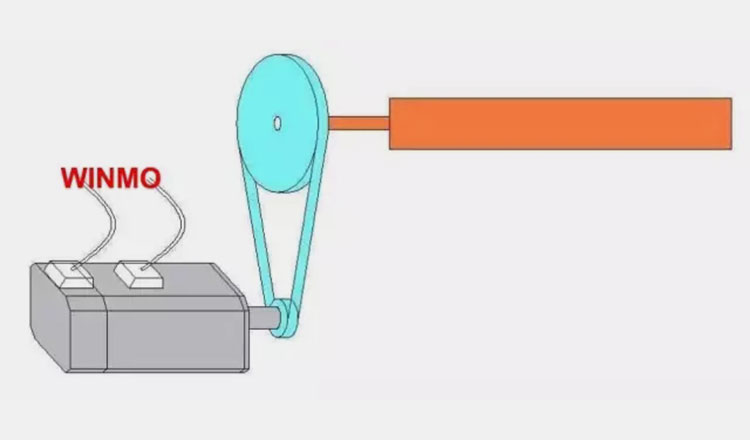

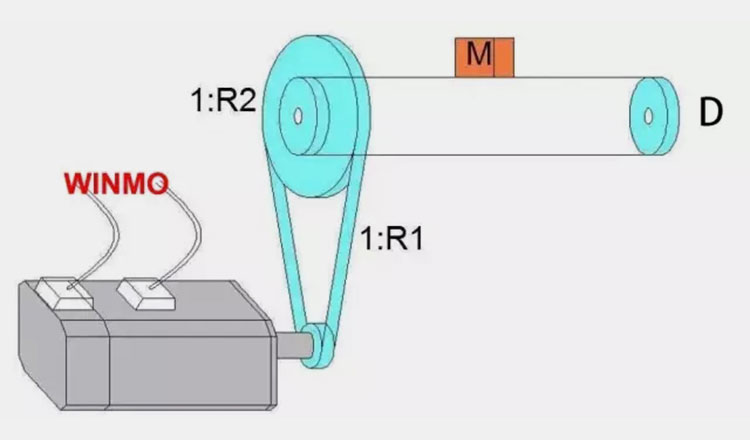

Known: load weight M=50kg, synchronous pulley diameter D=120mm, reduction ratio R1=10,R2=2, friction coefficient between load and machine μ=0.6, load maximum speed 30m/min, load acceleration time from rest to MAX speed 200ms, ignoring the weight of each conveyor pulley, how much power motor is the minimum required to drive such a load?

Example calculation 2

1. Calculate the load inertia converted to the motor shaft

JL = 4 M * D squared / / R1 squared = 50 * 144/4/10 0 = 18 kg. Cm squared

The principle of installing load inertia < 3 times of motor rotor inertia JM JM > 6kg.cm²

2. Calculate the torque required by the motor to drive the load

The torque required by friction is overcome

Tf=M*g*μ*(D/2)/R2/R1

=50*9.8*0.6*0.06/2/10

=0.882N.m

Torque required for acceleration

Ta=M*a*(D/2)/R2/R1

=50*(30/60/0.2)*0.06/2/10

=0.375N.m

Servo motor rated torque > TF, MAX torque BBB> + TA

3. Calculate the required speed of the motor

N=v/(πD)*R1

=30/(3.14*0.12)*10

=769rpm

According to the above data analysis, the minimum motor SM1301520 can be selected.

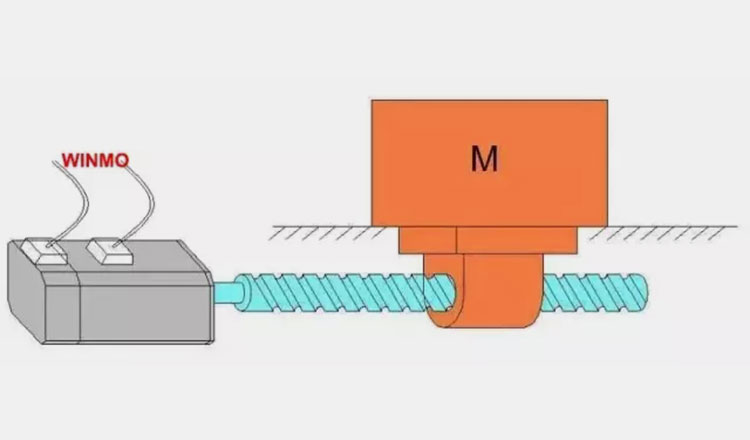

Example calculation 3

Known: load weight MB=200kg, screw pitch PB=20mm, screw diameter DB=50mm, screw weight MB=50kg, friction coefficient μ=0.2, mechanical efficiency η=0.9, load moving speed V=30m/min, the whole moving time T =1.4s, acceleration and deceleration time T1 = T3 =0.2s, static time T4 =0.3s. Please select the minimum power servo motor to meet the load requirements.

1. Calculate the load inertia converted to the motor shaft

The moment of inertia of a weight converted to the shaft of the motor

JW=M*(PB/2π)²

=200*(2/6.28)²

=20.29kg.cm²

The moment of inertia of the screw

JB=MB*DB²/8

=40*25/8

=125kg.cm²

Total load inertia JL=JW+JB=145.29kg.cm²

2. Calculate motor speed

Required speed of motor

N=v/pb

=30/0.02

=1500rpm

3. Calculate the torque required by the motor to drive the load

Torque required to overcome friction

Tf=M*g*μ*PB/2π/η

=200*9.8*0.2*0.02/2π/0.9

=1.387N.m

The torque required when a heavy object accelerates

TA1=M*a*PB/2π/η

=200*(30/60/0.2)*0.02/2π/0.9

=1.769N.m

The torque required to accelerate the screw

TA2=JB*α/η=JB*(N*2π/60/t1)η

=0.0125*(1500*6.28/60/0.2)/0.9

=10.903N.m

Total torque required for acceleration Ta = Ta 1+ Ta 2=12.672N.m

Another way to calculate the required acceleration torque:

TA=2π*N(JW+JB)/(60*t1)/η

=6.28*1500*0.014529/12/0.9

=12.672N.m

Calculate the instantaneous maximum torque:

To speed up the torque Ta=TA+Tf=14.059N.m

Uniform torque Tb=Tf=1.387N.m

Deceleration torque Tc=TA-Tf=11.285N.m

Results the torque

Trms=sqrt[(Ta²*t1+Tb²*t3)/(t1+t2+t3)]

=sqrt[(14.059²*0.2+1.387²*1+11.285²*0.2)/(0.2+1+0.2)]

= sqrt[(39.531+1.924+25.47)/1.4]

=6.914N.m

4. Select servo motor

Servo motor rated torque T>Tf and T>Trms

Max torque of servo motor Tmax>Tf+TA

Finally, the SM180 motor was selected

⊙Turn the way

⊙The load weight

⊙Belt pulley/ball screw and other transmission parts weight

⊙Reduction ratio

⊙Pulley diameter/ball screw pitch

⊙Acceleration and deceleration characteristic

⊙The running speed

⊙The coefficient of friction

⊙Mechanical efficiency

Winmo originated in Germany, rooted in China, is committed to becoming an enterprise superior to management and advocating high-tech; We provide our customers with leading automation solutions according to their needs.

Winmo has become one of the leading suppliers of industrial automation products with high quality products, leading solutions and customer-oriented service.

Everything we do serves our mission - "Technology creates a better life". Adhere to scientific and technological innovation, continuous improvement of products, to bring you more choices and values, to meet your application needs, so that your products have a decisive competitive advantage in the industry.

Contact us

Winmo (china) technology Co.,Ltd.

China Operation Center:

Room 301, Building 5, No.2899, Lianhua South Road, Minhang District, Shanghai

Tel: 021-51097178 / Fax: 021-54307800

[scan]

[scan]